How are EXCELLENCIAL product inspections performed?

Excellencial performs product inspections services according to:

- Recognized international quality standard: ISO 2859-1 (ANSI/ASQC Z1.4-2003), also known as the AQL Tables, unless another standard is requested by the client.

- Client’s requirements, specifications, criteria and instructions.

- EXCELLENCIAL team’s expertise and experience in quality control.

- EXCELLENCIAL Western common sense.

What do we inspect during an inspection?

- The quantity produced (semi-finished, finished and packed)

- The visual appearance (cosmetic check of the mass production)

- The product specifications (size, dimensions, colors)

- The labeling and marking

- The packing and packaging

- All possible functions and possible tests (safety, abuse, printing, etc.)

What quality standards do we use for inspections?

Based on the sampling size chosen from the AQL tables, we carefully ensure to select production samples randomly. We inspect the samples and classify the defects into critical, major and minor defects. We use detailed check lists for these definitions – our clients are invited to make amendments.

According to the number of defects found for each type and according to the number of defects allowed (figures given by the AQL tables), we will advise you to accept or to reject your shipment.

Then it is up to you to make your own decision based on the information and recommendations we have provided to you. We suggest that you discuss the findings with your vendor and the manufacturer and you ask him to pay attention/rework/re-produce/sort out the products.

How to use the AQL Tables?

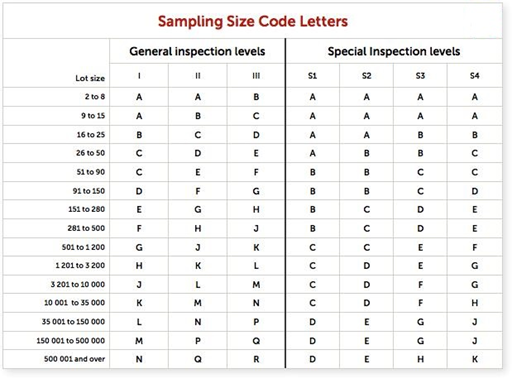

The AQL tables will help to determine the sampling size we will need to inspect according to your ordered quantity and your level of severity (I, II or III). The standard level, the one used by default and by 98% of the people is the level II for a standard inspection. If your order has multiple references, ideally we should at least inspect a level II on each reference.

Indeed, for a standard order, the standard level II from the AQL gives the minimum sampling size we should check per reference if we do not want to take additional risks. If we inspect a general level II sampling size on a multiple references orders, then the sampling size is diluted and divided by the number of references, increasing the risks as the sampling size must be representative enough.

How to find your sampling size on the AQL table?

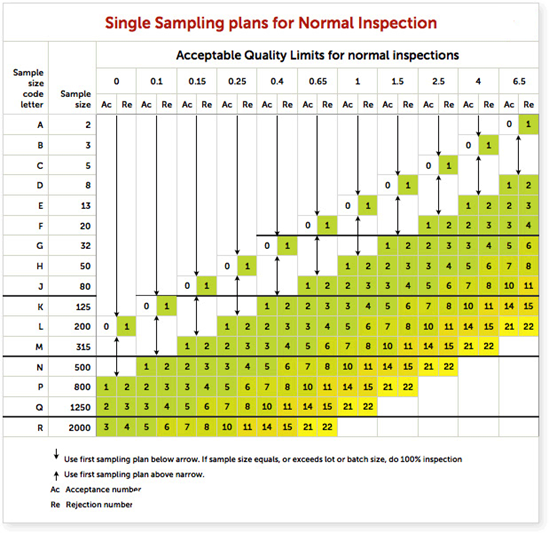

In order to find the necessary sampling size to be inspected, we look at the first chart and find on the left side the range of items being produced in total. You have the choice of levels I, II and III, with Level III being the most stringent testing and level I being the least. Level II is the standard and is most often used. For example, if you are producing 8000 items, at level II you have the letter L, which in the second table says to inspect 200 items.

On the top of the second chart are the defect levels, ranging from 0 to 6.5. You can choose which level to apply for your type of defect: critical, major and minor. Usually most importers will choose standard defect levels which are 0/2.5/4 but one can choose 1/1/1 if he wishes or 0/1.5/2.5 like in the automotive industry. Using the standard 0/2.5/4 defect levels and a sample size of 200, we see that if you have more than 0 critical defects, 10 major defects or 14 minor defects, you should reject your shipment. Of course the decision about what to do after your received the inspection results belongs to you. Most importers will wish to discuss all inspection findings with their vendor/manufacturer in order to improve whatever possible. In case the inspection results are very close to AQL limits, it is important that you double check if the level of found defects is acceptable to you or not.

It is not my first time to pay a quick visit this website, i am visiting this website dailly and obtain pleasant facts from here everyday.

Hi, I do think this is a great web site. I stumbledupon it 😉 I may come back once again since I book marked it.

Money and freedom is the best way to change, may you be rich and continue to help others.

Hi there, its fastidious article regarding media print, we

all be familiar with media is a enormous source of information.

Also visit my homepage BodyCore Keto Reviews

I am not sure where you are getting your information, but good topic.

I needs to spend some time learning more or understanding

more. Thanks for excellent info I was looking

for this info for my mission.

My web site :: Inez

Hmm is anyone else having problems with the pictures on this blog loading?

I’m trying to find out if its a problem on my end

or if it’s the blog. Any feed-back would be greatly appreciated.

my homepage :: Gorges De Soleil Anti Wrinkle Cream Reviews

I all the time used to read article in news papers but now as I am a user of web so from now I

am using net for articles, thanks to web.

My homepage :: forum.adm-tolka.ru

Genuinely no matter if someone doesn’t understand

afterward its up to other viewers that they will

assist, so here it happens.

Feel free to visit my site :: Gorges De Soleil Cream

Borgata utilizes the most current in safety technologies and is legally

licensed in all states.

I like this weblog very much, Its a rattling nice berth to read and find

information.

My web page – Slim Belly Fix PDF

Really informative and great anatomical structure of subject material, now that’s user pleasant (:.

Stop by my blog post Gorges De Soleil Anti Wrinkle Cream

You completed some nice points there. I did a search on the theme and found a good number of folks will

go along with with your blog.

Feel free to surf to my web site; mpc-install.com

thank you for all your efforts that you have put in this.

Very interesting info.

Feel free to visit my web-site: Gorges De Soleil Cream

What’s up everyone, it’s my first visit at this site, and paragraph is truly fruitful designed for

me, keep up posting these articles or reviews.

Feel free to surf to my site; ace333

Hey I know this is off topic but I was wondering if you knew

of any widgets I could add to my blog that

automatically tweet my newest twitter updates.

I’ve been looking for a plug-in like this for quite some time and was hoping maybe you would have some experience with something like this.

Please let me know if you run into anything.

I truly enjoy reading your blog and I look forward to your new updates.

my page Muama Translator

It’s very simple to find out any matter on net as compared to textbooks, as I found this article at this

website.

fantastic points altogether, you just received a brand new reader.

What could you suggest about your post that you simply made some days in the past?

Any positive?

Here is my blog :: Nitro Strive Review

What a information of un-ambiguity and preserveness of precious familiarity about unpredicted emotions.

my web page Ice Box Air Cooler

Post writing is also a excitement, if you be familiar with after

that you can write otherwise it is complex to write.

Feel free to visit my blog post: Gorges De Soleil Anti Wrinkle Cream Price

Heya i am for the primary time here. I came across this board and I find It

really useful & it helped me out much. I hope to give something

back and aid others like you helped me.

Its like you read my mind! You appear to know a lot about this,

like you wrote the book in it or something. I think that you can do

with a few pics to drive the message home a bit, but other than that, this is

magnificent blog. A great read. I’ll certainly be back.

Also visit my webpage: Paramore Cream Ingredients

What’s up, yup this piece of writing is really good

and I have learned lot of things from it concerning blogging.

thanks.

For newest information you have to pay a quick visit web and

on the web I found this website as a best site

for newest updates.

What’s Happening i’m new to this, I stumbled upon this I have found It

absolutely useful and it has helped me out loads. I hope to give a

contribution & help other customers like its helped me.

Good job.

You made some decent points there. I checked on the

web for more info about the issue and found most people will go along with your views

on this site.

Thank you for the auspicious writeup. It in fact was a amusement account it.

Look advanced to more added agreeable from you! However, how could we communicate?

Hurrah, that’s what I was looking for, what a data! existing here at this webpage, thanks admin of this web page.

It’s going to be end of mine day, except before finish I am

reading this fantastic piece of writing to increase my knowledge.

Amazing issues here. I am very glad to look your post.

Thank you so much and I’m having a look forward to contact you.

Will you please drop me a e-mail?

I read this piece of writing fully on the topic

of the difference of most up-to-date and preceding technologies,

it’s awesome article.

Hi there very nice blog!! Guy .. Beautiful ..

Superb .. I will bookmark your blog and take the feeds

also? I am satisfied to search out a lot of helpful info

here within the put up, we want develop more strategies in this

regard, thanks for sharing. . . . . .

Everything is very open with a really clear description of the challenges.

It was truly informative. Your website is

useful. Many thanks for sharing!

Hello There. I found your weblog using msn. That is a really well written article.

I will make sure to bookmark it and come back to read more of your helpful information. Thank you for the post.

I’ll certainly return.

What’s up everyone, it’s my first go to see at this site,

and paragraph is really fruitful in support of me, keep up posting these types

of articles.

my blog – Cool Wave Air Conditioner

I am truly delighted to glance at this webpage posts which carries

plenty of helpful data, thanks for providing such statistics.

Look into my web site … Alive CBD

Thank you for another wonderful post. Where else could anyone

get that type of information in such a perfect approach of writing?

I have a presentation subsequent week, and I am at the search for such information.