Having a smooth supply chain process is a dream for every importer no matter where to source the products. However, problems can occur at any time and affect the production. Therefore, knowing where the problems are coming from by conducting production monitoring is necessary.

Here are three reasons to conduct the production monitoring:

1. PRODUCTION MONITORING GIVES AN INSIGHT INTO THE PRODUCTION

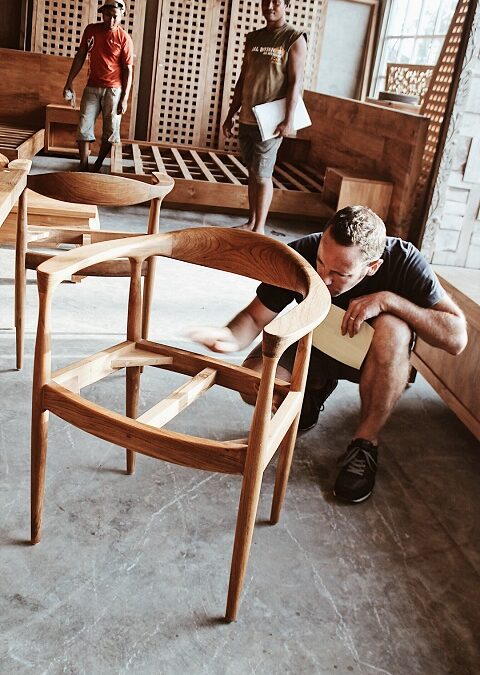

Conducting production monitoring is really beneficial for the importers. It will give you a complete insight of the manufacturing process from the very beginning until the goods are ready to be shipped. Usually, production monitoring is a combination between three inspections, i.e.

- Pre-production inspection: Controlling the raw material and other key components before the factory starts to manufacture the goods.

- During production inspection, giving insight of the product specifications and appearance, packaging, and status and quantity of the product (ready, unpacked, and still in production)

- Pre-shipment inspection, ensure that quality, quantity, packaging and labeling conform to your specifications and approved master samples.

By conducting the production monitoring, importers will have a full insight of the production. This will be beneficial in a number of ways, including revealing how factory workers operate and the implications for your product.

2. PRODUCTION MONITORING HELPS PREVENT SHIPPING DELAYS

Production and shipping delays are the most frustrating issues for the importers. One of the reasons is the lack of transparency between the supplier and buyer. Production monitoring—and to a less extent, product inspection—offers transparency to help importers forecast and prevent delays that might otherwise lead to customer dissatisfaction.

3. PRODUCTION MONITORING IDENTIFIES ISSUES FASTER

When you find defects on the products after production has finished—or even worse, after the goods arrive at your customer—it will be difficult to solve, and it will affect your brand image because the customers think you are selling a bad quality product .

By conducting production monitoring, it enables you to get the report of your production stage and the inspector can note any product issues and notify you that day. Following their report, you could then advise the supplier of any issues found and prevent them from affecting the entire order.

For some factories, this early detection of problems can be especially helpful. Management and workers may be accustomed to reworking defective products. But having an inspector identify defects before the goods reach their customer saves them from wasting time, and possibly, from losing that customer’s future business. Furthermore, helping a factory improve its manufacturing processes often improves the relationship you have with your supplier

Production monitoring gives you knowledge of the entire manufacturing cycle, points out any defects at all stages and helps prevent shipping delays. And when you understand and control your manufacturing from start to finish, that can only mean two things: better product quality and happier customers.