The Challenge

As the markets become more and more competitive, retailers, importers and buyers need a healthy vendor’s pool and a reliable supply chain. But how to select the right vendor? How to control the improvement of your actual vendor? How to efficiently work with your Indonesian supplier in order to ensure better quality day after day?

The Solution

The Factory Audit in Indonesia makes sure that the selected factory has the resources to complete your order and that the products will be made in good conditions. This due diligence should be systematically part of your quality assurance program.

Factory Audits are performed according to:

- Recognized international quality standards, norms & regulations

- Client’s requirements, specifications, criteria and instructions.

- Excellencial team expertise and experience in quality control.

- Excellencial Western common sense.

Quality Management Audits – ISO 9000

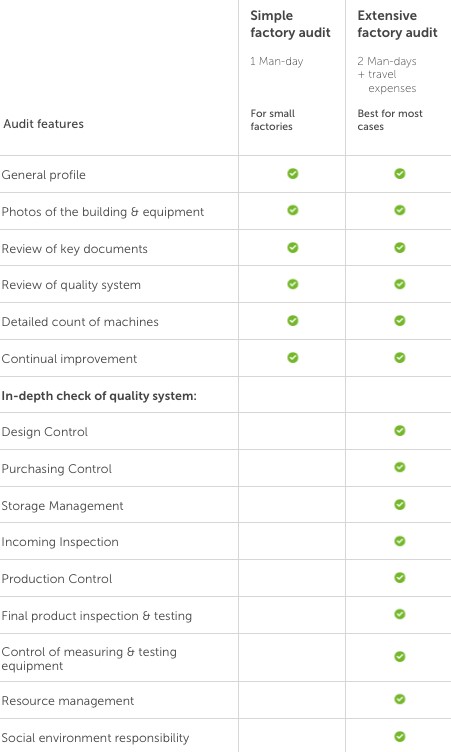

Excellencial’s Simple Factory Audit and Extensive Factory Audit are both based on a checklist derived from the ISO 9000 series (a set of quality standards developed in 1987 by the International Organization for Standardization). Quality management audit reports shall cover the following verifications:

- Quality Management System

- Production processes

- Quality of the produced products (available at the time of the audit)

- Work force and working conditions

When are Factory Audits in Indonesia performed?

The Factory Audits should be performed when you have short-listed several potential vendors. You can choose between a Simple Factory Audit and an Extensive Factory Audit.

Where are Factory Audits performed?

The Factory Audits in Indonesia are done at the manufacturer’s premises, while most clients are usually just in touch with sales offices or vendors.

Your benefits when booking our Factory Audit services:

- Avoid scams and inexperienced vendors.

- Know if you are dealing with an agent or factory.

- Check factory’s experience in manufacturing your product(s).

- Discover manufacturer’s strengths and weaknesses.

- Check if your chosen factory has the relevant and needed certificates and licenses.

- Compare potential vendors and choose the right partner(s) who fits your needs.

- Improve your collaboration with existing partners and factories.

Factory Audit reports verify the following: